- Contact Person : Mr. Guo bob

- Company Name : Maanshan RH Tooling Co., Ltd.

- Tel : 0086-555-6718110

- Fax : 0086-555-3776393

- Address : Anhui,Maanshan,bowang economic development area

- Country/Region : China

- Zip : 243131

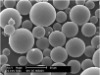

Hollow glass microspheres for Thermal Insulation Paint and Coating

"Not agent/distributor!Just show the products we are manufacturing professionally on this site to attract more oversea business! Free sample!''

High-performance hollow glass microspheres is a kind of ultra-lightweight inorganic non-metallic powder with hollow microsphere, and it is a versatile and high-performance new lightweight material developed in recent years. It will be the new mainstream materials for composites at 21 century.

Benefits for Thermal Insulation Paint and Coating :

1. Hollow glass microspheres have the smallest surface area and low oil absorption rate, can significantly reduce the consumption of other components in paint.2. The vitrified surface of glass microspheres can realize the chemical corrosion resistant, and reflexaction on light. Therefore, the paint can prevent from fouling, corrosion, UV, yellowing and scratching etc.3. Thin gas inside the hollow glass microspheres with compact arrangement, makes low thermal conductivity, so that paint coating has a very good effect on heat insulation.4. Hollow glass microspheres can effectively enhance the fluidity and smoothness of coating.5. Hollow glass microspheres contain gas inside, so it has a good contractility resistance to hot and cold, thus enhancing the flexibility of coating, greatly reducing the cracking and peeling of the coating due to thermal expansion and contraction.6. On premise of high filling level, the viscosity of paint will not be significantly increased, thus reducing the usage of solvents. It can reduce toxic gas emissions in the process of painting, and VOC indicator can be effectively reduced.

Dosage recommendation:The addition is normally about 10-20% of the total weight. Adding methods are proposed as follows: The hollow glass microspheres are proposed to add at the last step, and dispersed with low-speed, low shearing force mixing equipment. Due to its good liquidity,small friction, so it willeasily dispersed into mixture to completely keep wet within a short time. Through slightly extending mixing time can achieve uniform dispersion. Hollow glass microspheres are inert and non-toxic. Due to its light weight, attention should be specially paid when adding. We recommend adding the microspheres by step, that is, the addition quantity is 1 / 2 of the remaining beads each time. It can well avoid the microspheres floating into the air and make it disperse even more completely.

Recommended models for Building Coating :H32 H40

Recommended models for General Industrial Paint and Coating:H46 H60

Recommended models for Pipeline Storage Tank:H32 H40

Hollow glass microspheres for Thermal Insulation Paint and Coating